EMC(Electromagnetic Compatibility)is the ability of a device or system to function properly in its electromagnetic environment without posing an unbearable electromagnetic nuisance to anything in that environment.

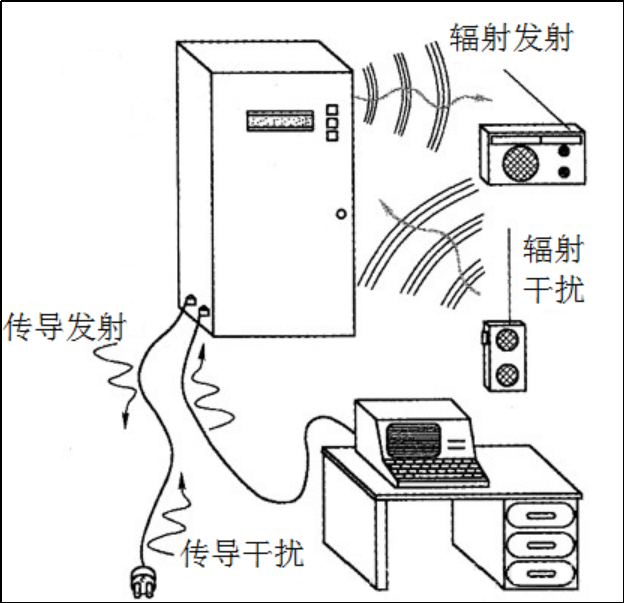

Any electronic device emits electromagnetic disturbances in two ways: one is through space, called radiated emissions; the other is through cables and conductors, called conducted emissions. Corresponding electronic device also needs to have the ability of radiation anti-interference and conduction disturbance anti-interference.

On the one hand, it means that the electromagnetic disturbance generated by the device to the environment during normal operation cannot exceed a certain limit, which is called EMI (Electromagnetic Interference);

EMC=EMI+EMS

01 Adhering to The Company's Mission & Improving Product Positioning

According to international standards, national standards, industry standards or company standards to verify the achievement of product EMC project design, solve product EMC weaknesses, and promoting product positioning with professional technology.

02 Improve The Pass Rate of Product Certification Test

Improving the pass rate of products in certifiability tests through pre-compliance testing.

03 Add More Guarantee to the Product

Promote EMC design to provide a basis for stable and reliable industrial control products.

04 Keeping Up With The Latest Technology

Real-time follow-up of cutting-edge EMC testing technology to keep in line with international mainstream EMC requirements.

Lab Enviroment Overview

Shielded Room

Conductive Emission Test Environment

Conducted Disturbance Immunity Test Environment

Burst, Surge And Voltage Dip Immunity Test Environment

Electrostatic Discharge Immunity Test Environment

High Frequency Impulse Noise Immunity Test Environment

简体中文

简体中文